Hoosier Feeder Company

Home » Suppliers » Hoosier Feeder

Hoosier Feeder specializes in high quality and efficient feeding, orienting, and conveying equipment designed to optimize our customer’s automated processes. Our extensive experience and industry knowledge enable us to design and implement the most effective industrial feeder systems. Our solutions are used in a variety of industries from packaging and processing to automotive, medical, pharmaceutical, food processing, general manufacturing, electronics, and many more.

Hoosier Feeder Featured Products

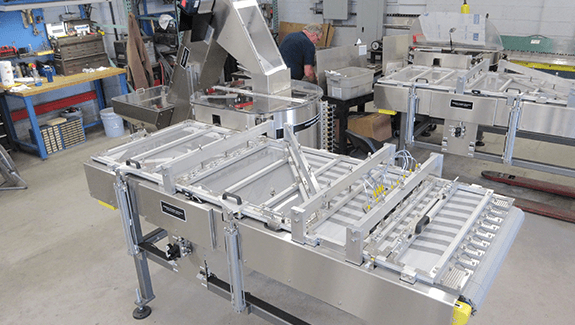

Hoosier – Vibratory Feeders Vibratory Feeders are used to orient and discharge parts in a repeatable position for the assembly process. Hoosier Feeder Company is a vibratory feeder manufacturer whose feeder systems bring value through their capability to feed multiple part styles …

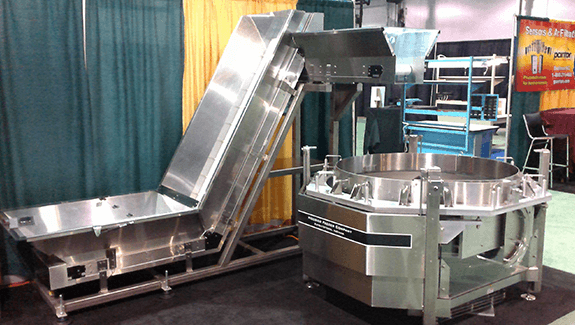

Hoosier – Centrifugal Feeders The centrifugal feeder systems manufactured at Hoosier Feeder Company are specifically designed with quality and efficiency in mind. Our proficiency and experience with rotary bowl systems allow us to handle complex applications effectively at high rates of speed. …

Hoosier – Flex Feeders As the robotics industry continues to influence manufacturing, feeding technology must adapt to supplement its growing presence. The HFC flex feeders are designed to present parts in a consistent array so that robots guided by vision inspection can effectively …

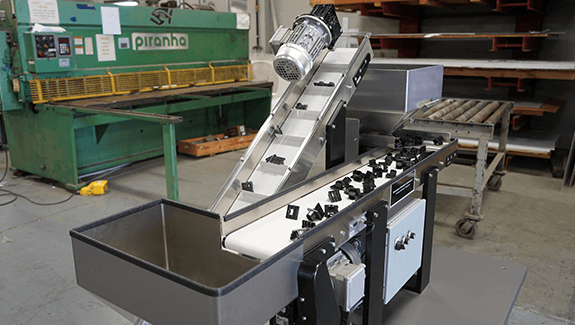

Linear feeders handling systems come in a variety of shapes, sizes, and styles to fit your specific application. Although all of the styles have their advantages, their job is to move parts from one location to another, sometime traveling long distanced …