LinMot develops, manufactures and distributes high-quality linear motors, linear rotary motors, linear modules and linear systems for use in industrial automation. You get everything for linear motion from a single source. The headquarters of NTI AG is located in Spreitenbach, near Zurich in Switzerland. As an international, innovative company with an experienced customer service, sales and support network, we are always a competent and reliable partner for the realisation of linear and rotary movements.

Home » Suppliers » LinMot

Featured LinMot Products

LinMot – Linear Motors LinMot motors are high quality, extremely high efficiency tubular linear motors. This high efficiency means less heat generated and better position accuracy. The simple, clean tubular design makes it easy to install the motor, reducing the …

LinMot – Linear Actuators (F01/E01) Both the F01 and E01 modules are part of the moving stator applications with linear tubular motors. Their mechanical construction is based on a special aluminum profile to which up to two high-precision profile rail …

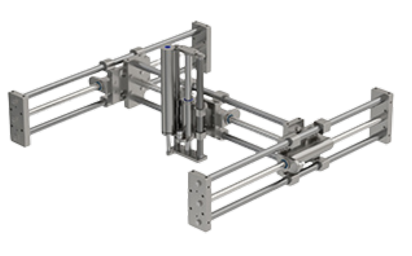

LinMot Robots offer a range of high-precision motion control systems, from the versatile AM01 to the robust AM14. Each model includes guides, drives, cables, and power supplies designed for smooth and accurate movement, making them ideal for various industrial applications. …

LinMot – IP69K Rated Solutions Developed for a demanding environment, the compact LinMot SSC linear motors are made of stainless steel EN 1.4404/AISI 316. In the construction of this motor family, the focus is on hygienic design. In order to prevent …

LinMot – Linear Actuators (DM01) The LinMot DM01 product family comprises a versatile range of linear modules designed for various industrial applications. At its core, the DM01 series features LinMot linear motors, including the PS01-23, PS01-37, and PS01-48 models. These motors offer …

LinMot – MagSprings Its functionality is based on the attractive force of permanent magnets. This means that no power supply is needed (electrical power, compressed air, etc.), making even safety-related applications possible. Due to the special design of the flux …

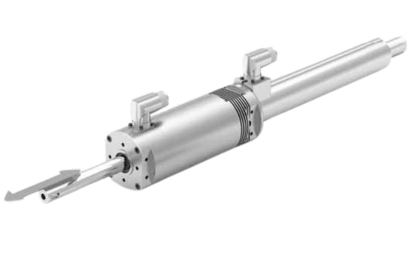

LinMot Linear Rotary Actuators seamlessly combine linear and rotary movements within a single, compact housing. These advanced actuators offer unparalleled flexibility, dynamics, and speed, making them ideal for diverse industrial applications. Moreover, with the ability to perform both linear and rotary …

LinMot – IP69k Stainless MagSprings MagSpring products are best described by the term “magnetic spring”. The term “spring”, however, must be understood in the sense that MagSpring components exert a constant force over their entire working range, whereas a typical …

The AM03 from LinMot is a robust motion control system designed for precision applications. It includes one EM01 or FM01 guide for the X axis, one DM01 guide for the Z axis, two C1250-MI drives, two 4-meter cables, one S02-72/1000 …