Precision Stages & Actuators

Home » Products » Precision Stages & Actuators

Precision Actuators/Stages are designed to meet higher specifications of positioning (accuracy & repeatability) as well as smoothness of travel (roll, pitch & yaw). Typically these stages are used in applications where positioning not only matters but is critical to application success.

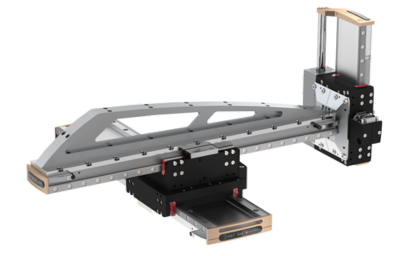

Jenny Science – Multi Axis Systems All Jenny Science linear and rotary actuators have been designed to be configured with each other, with machined features to ensure orthogonality. …

Jenny Science – INTAX New paths are created by going down them. The innovative performance of this completely new developed linear motor stage is an unprecedented packing density by integration of servo controller, wiring and cable drag. This new benchmark in …

Jenny Science – ELAX These new, electric linear motor slides ELAX® Ex from Jenny Science are predestined for fast and precise pick and place units! Furthermore, the programmable force control processes open new application possibilities in handling, assembly and inspection. With …

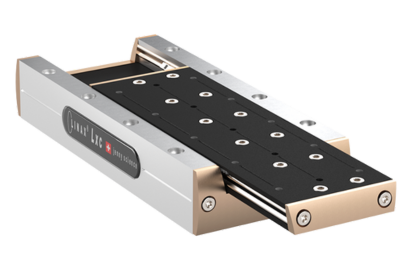

The Jenny Science Linax family of linear motor axes, including the Lxc, LXx F60, Lxe, Lxu, and LXs F120 models, are designed to deliver high precision and performance across a variety of applications. Whether you are working in automation, robotics, …

The Jenny Science ROTAX Rxvp stands out in the world of high-performance engineering with its cutting-edge design and exceptional reliability. As a leader in advanced technology solutions, Jenny Science offers the ROTAX Rxvp, renowned for its precision and efficiency in …

The Jenny Science ROTAX Rxvp stands out in the world of high-performance engineering with its cutting-edge design and exceptional reliability. As a leader in advanced technology solutions, Jenny Science offers the ROTAX Rxvp, renowned for its precision and efficiency in …

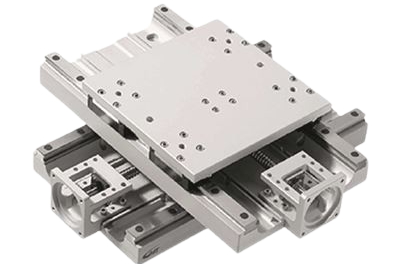

NTN Automation – Precision Stages NTN Automation provides a wide variety of precision motion applications. For manual tip/tilt stages to XY microscopy precision stages, NTN Automaton offers an extensive lineup of solutions. …